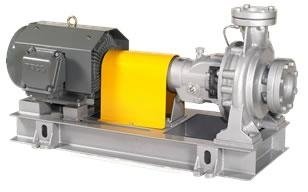

| Specification |

- Flow: Up to 1.6 m3/min

- Pressure: Up to 30 kg/cm2

- HP: 1~75 HP

- Liquid temperature: 0℃~150℃

- Liquid viscosity: 1 cp ~ 500,000 cp

- Shaft seal: Gland packing, mechanical seal

- Bearing bracket: Standard full close type

- Transmission: Belt driven

|

|

| Applications |

- Food industry: syrup, spices, jam, milk, cream, and other viscous drinks, etc.

- Petrochemical industry: Lubricating grease, heavy oil and asphalt

- Chemical products: Acetone, Ethyl alcohol, gelatin and DOP

- Drugs: Carbon dioxide, benzene and chloride

- Plastic and synthetic resin: styrene, plasticizer

- Coating industry: Coating material, ceramic paint and regular paint

- Textile industry: Conveyance of synthetic fiber materials

|

|

| Features |

- Inside connection type gear structure, gear style of optimized design, least wear, low noise.

- Belt transmission, using pulley to reduce rotating speed, suitable for high-viscosity liquid

- Simplified construction, easy disassembly of side cover of pump, accessible for routine maintenance

- Axial clearance of driving gear can be adjusted on exterior, without having to disassemble the pump

- Super powerful suction force, maximum up to 740mmHgG(20Torr)

- May install casing steam jacket

- May choose built-in safety valve, to prevent damage in case of overloaded pump

- May adopt internal gear external shaft design in conveyance of liquid containing fine solid particles

|

|

| Optional accessories |

- 3-Phase induction motor: 208~480V 60/50Hz

- Butt joint flange

- Motor speed reducer

- Motor speed changer

- Pressure gauge

- Composite gauge

|